Traceability to Mill (TTM)

At Pacific Inter-Link (PIL), we are committed to building a transparent, responsible and sustainable palm oil supply chain. Through full Traceability to Mill (TTM), we ensure that every delivery of palm oil can be traced back to its origin in line with our No Deforestation, No Peat, No Exploitation (NDPE) commitments.

PIL does not own any upstream plantations or mills. Instead, we source from third-party supplying mills located across Malaysia and Indonesia. Our affiliates procure Crude Palm Oil (CPO) from third-party mills in both countries, while Crude Palm Kernel Oil (CPKO) is sourced exclusively from Kernel Crusher Plants (KCPs) in Indonesia. Our oleochemical and soap manufacturing facilities source refined materials directly from our refineries in Indonesia.

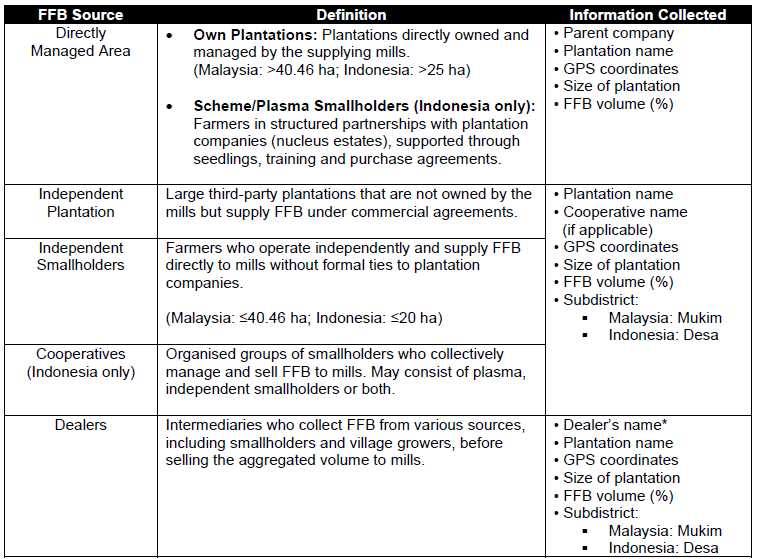

Our TTM programme covers both CPO and CPKO supply chains. The data, which includes parent company names, mill names, RSPO certification status, geo-coordinates and Universal Mill List (UML) IDs is updated and published biannually.

By sharing this information transparently, we aim to enhance accountability, strengthen supplier engagement and drive continuous improvements across our supply chain.

- Pacific Oils & Fats Industries Sdn Bhd

- PT. Pacific Palmindo Industri